|

|

|

|

|

|

|

|

Integrated Life Safety

Testing Solutions Inc.

|

|

|

|

|

Simplified, fully compliant testing that's both economical, safe and reliable! Simplified, fully compliant testing that's both economical, safe and reliable! Building Owners and Operators can leverage faster, reliable, more efficent testing and service! Building Owners and Operators can leverage faster, reliable, more efficent testing and service! The three amp switching current allows seamless, fully compatible integration with any fire alarm system! The three amp switching current allows seamless, fully compatible integration with any fire alarm system! Fully compliant testing of Data Communication Link (Signalling Line Circuit) Isolators in as little as sixty (60) seconds! Fully compliant testing of Data Communication Link (Signalling Line Circuit) Isolators in as little as sixty (60) seconds!

|

|

Accurate

Compliant

Economical

Easy Testing Technology

|

|

Our Mission:

To provide advanced, economical and sustainable testing solutions for building owners, operators, and technicians performing inspection, maintenance and service of building life safety systems and equipment.

|

|

|

|

|

Frequently Asked Questions (FAQ)

|

|

Click on a question to expand or collapse the answer window!

|

|

|

- What's the annual testing requirement for Data Communication Link (DCL) isolators?

|

Data Communication Link (DCL) - also referred to as Signal Line Circuits (SLC) ensure survival of the two wire communications loop which serves addressable (sometimes referred to as “analogue”) fire alarm field devices (smoke detectors, pull stations, heat detectors, etc.). Many of the more popular isolators out there are what’s termed “dumb” devices (in other words, they don’t have much in the way of internal “smarts”). They’re essentially a relay module that’s designed to isolate a short on the data circuit within a certain area or that may affect a number of devices assigned to the isolator. Regardless of what method they employ to identify a fault on the data loop, their main function is to isolate that fault to a few devices while ensuring the overall integrity of the system isn’t compromised.

Conventional Testing Method:

- There are two termination points on every isolator. You’ll have to remove the device cover to access the terminals. One is an “in” from the common data loop and the other is an “out” to the field devices it serves. Remove the wire from the “out” terminal. Programmed field devices associated with the protected portion of the circuit will also indicate a communications fault (if the loop is wired as Class “A” Style “A” or Class “A” Style “C” only an “open trouble” should indicate). If you’re conducting a Verification, proceed with testing devices on either side of the “open” in the circuit as required by the Standard.

- Restore the circuit. Some fire alarm controls will have to be “Reset” to clear the “open trouble”.

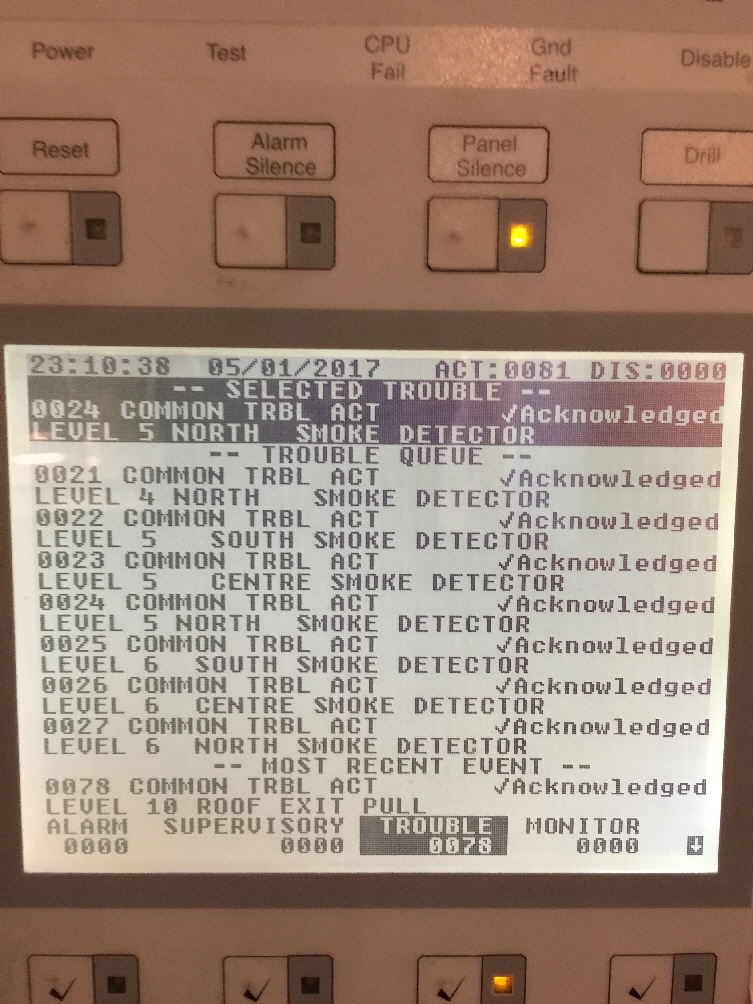

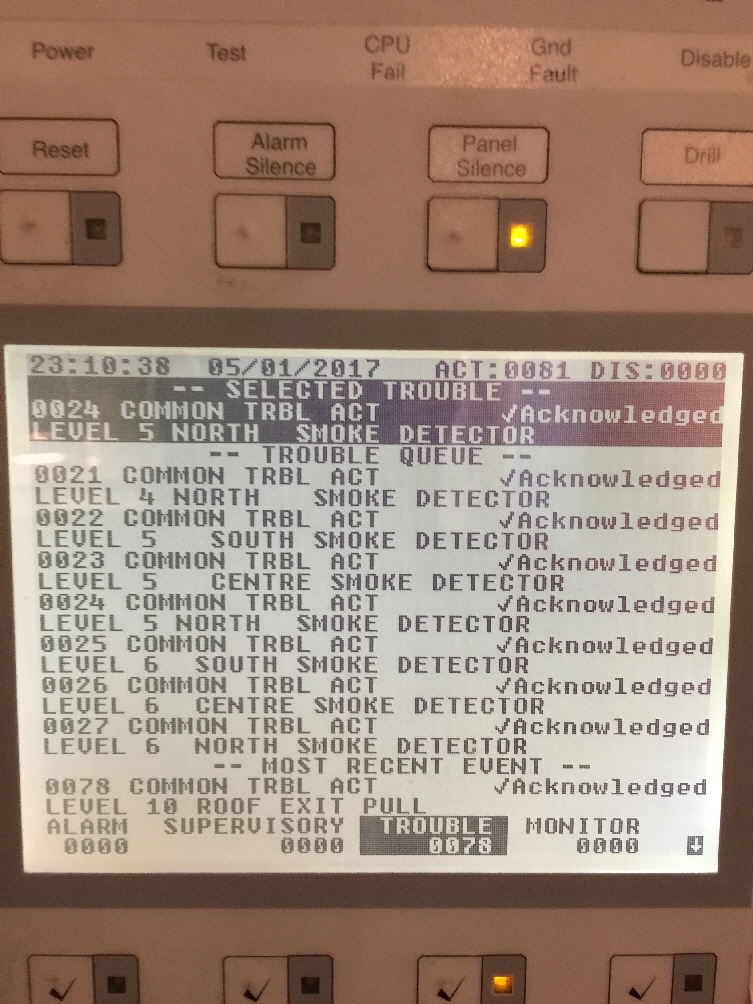

- Short the “out” side to ensure the unit functions correctly. Depending on the number of devices on the “out” side, you should see a string of error messages on the common control that are most commonly identified by the phrases “missing device” or “device error”, or “data loop short”. Maintain the short until you have scrolled through and noted each device that fails to report. Part of your “test” ensures that the total number of devices for each isolator does not exceed the manufacturer’s maximum limit. (Important Note: If more than one floor area’s devices fail to report while the short is in place you will have to note this as a deficiency on your report!)

- With the short still in place, initiate the required testing for devices connected to the same loop controller outside of the floor area served by the isolator under test.

- Remove the short, and re-install the isolator. You will have to reset the system before proceeding to the next isolator on the loop.

Note: Field devices which employ isolator bases must also be tested. If the system you’re testing employs these units (it’s usually the first smoke detector on the loop), you’ll have to find an addressable device (a manual station is usually the easiest to access) downstream of the isolator. Drop it and short the loop terminals from here. Maintain the short and have your helper scroll through and note each device that fails to report.

Make sure the device is labelled correclty (i.e. the zone or area it’s protecting).

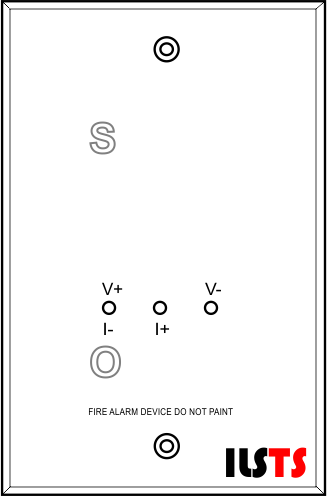

Testing Method With ILSTS UEI-1 Universal Alarm Circuit / Isolator Test Point

|

|

|

- Place a magnet on the letter “O” (Open) on the face of the ILSTS UEI-1. This will impose an “open” on the circuit which will indicate an “open trouble” at the common control. Programmed field devices associated with the protected portion of the circuit will also indicate a communications fault (if the loop is wired as Class “A” Style “A” or Class “A” Style “C” only an “open loop trouble” should indicate). If you’re conducting a Verification, proceed with testing devices on either side of the “open” in the circuit as required by the Standard.

- Remove the magnet. The circuit should return to normal. Some control panels may require a “Reset”.

- Place the magnet used in Step 1 on the letter “S” (Short) on the face of the ILSTS UEI-1. This will cause a short condition on the circuit and activate a visible indicator on the isolator(s) being tested. Depending on the number of devices on the “out” side, you should see a string of error messages on the common control that are most commonly identified by the phrases “missing device” or “device error”, or “data loop short”. Maintain the short until you have scrolled through and noted each device that fails to report. Part of your “test” ensures that the total number of devices for each isolator does not exceed the manufacturer’s maximum limit. If more than one floor area’s devices fail to report while the short is in place you will have to note this as a deficiency on your report!

- With the magnet in place, initiate the required testing for devices connected to the same loop controller outside of the floor area served by the isolator under test.

- Remove the magnet. All indications for the designated loop controller at the control panel should read “normal”. Some control panels may require a “Reset”.

- Insert the test probe from your multi-meter into any one of the three holes located on the face of the unit and ground the other end of the probe against one of the exposed screws used to secure the plate to the electrical box. A “ground fault” condition should be indicated on the common control.

- With the “ground fault” condition active, complete the required testing procedure for connected fire alarm devices within the floor area.

- Remove the probe and the connection to the building ground. Circuit indications for the DCL (SLC) loop being tested should read “normal” at the common control. You will have to reset the system before proceeding to the next isolator on the loop.

You DO NOT need to remove any active (or conventional) field device(s), cover plates, or junction boxes on the circuit serving the floor area. The entire test using ILSTS UEI-1 takes about sixty seconds (depending on the time the “Reset” function takes for the system you’re testing)!

|

|

|

- Can I retrofit the ILSTS UEI-1 to work with my existing Data Communication Link (DCL) isolators?

|

You can deploy ILSTS UEI-1 into your existing system to facilitate future testing of your DCL (SLC in the United States of America) isolators. You will, in most instances require a building and electrical permit as you are adding devices to an existing fire alarm system. You will also have to engage the services of a Verifier in order to obtain an acceptable CAN/ULC-S537 Appendix “C” Report.

In most cases, the cost for the installation will be repaid within two (2) years with the savings you’ll realize from the reduced expense associated with your system’s annual inspection!

|

|

|

|

|

- What's the test procedure for suite signaling circuits employing isolators?

|

|

The NBC (National Building Code) mandates that insuite sounder devices must be installed on a separate signalling circuit from the common area notification appliances. Some designs may incorporate suite signal isolators. Where they’ve been required, these units are normally installed in the common area corridor outside of the suites they serve. They’re always located behind a suitable cover which identifies them as a fire signaling component or fire alarm device.

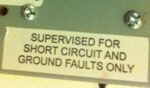

There are two tests which must be performed at each installed isolator on an annual basis. There are two “flavours” available: “supervised” and “unsupervised”, The unsupervised isolator is NOT allowed by Code or the installation standard (CAN/ULC-S524). If you come across one (they will have a label affixed to them identifying them as such), you must fail the unit. No further testing is required.

This is a label on an

UNSUPERVISED Isolator:

Caution! Use of ANY unsupervised

device on a fire alarm system in Canada

is prohibited by both Provincial/Territorial

Building Codes and CAN/ULC-S524!

Required Testing - There are two phases to the required testing. One is performed while the system is in normal supervisory mode, the other is performed while the system’s sounders are active. For these tests, it is recommended they be performed inside the suite the unit serves. You will notice that there are two “outputs” on each isolator (it serves two separate suites or units). All in-suite devices controlled by an isolator are wired in a Class “A” loop.

Conventional Testing Method:

Step 1 - Remove and drop any one of the in-suite buzzers.

Step 2 - Disconnect one of the terminals (or terminal leads). You should receive an “open” fault at the common control. If the isolator you’re testing happens to be a Potter/Amseco IS-S, then one of the LED’s should also illuminate on the cover. With the wire disconnected, have your partner initiate a “drill test”. The buzzer in your hand (and all the buzzers in the suite) should sound. This test confirms that the isolator module you’re testing supervises for “opens” and while not specifically mandated by the Standard will assist an AHJ in identifying a properly installed fire alarm system.

Step 3 - Reconnect the terminal.

Step 4 - Now short positive and negative together. Observe the display on the common control (as well as on the isolator - if applicable) and note it.

Step 5 - With the short still on, have your helper initiate a fire drill test. None of the buzzers in the suite should be sounding, but the buzzers on the other side of the isolator (as well as the other suites on the floor) should be unaffected.

Step 6 - With the system still in active “drill test”, REMOVE the short. The buzzer in your hand should start to sound.

Step 7 - Reinstate the short. The buzzer in your hand (as well as any others in the same suite) should all stop sounding. The buzzers in the other suite served by the isolator should continue to sound.

Step 8 - Have your helper deactivate the “drill test”.

NOTE: If, in step 5, none of the buzzers in the suites sound, then the notification appliance circuit is programmed incorrectly! You must note this on your report. Some systems utilize a jumper setting to activate the signals if isolators are on the circuit. Other systems require access to the physical panel programming to enable this feature.

If all of the above tests are completed satisfactorily, you can move on to the next suite on the floor (after reinstalling the buzzer that is!).

Testing Method Using ILSTS UEI-1 Universal Alarm Circuit / Isolator Test Point

- Place a magnet on the letter “O” (Open) on the face of the UEI-1. This will impose an “open circuit” on the NAC which should cause an “open trouble” fault signal at the common control. With the wire disconnected, have your partner initiate a “drill test”. The buzzers in the suite (and all the buzzers in the floor area) should sound. This test confirms that the isolator module you’re testing supervises for “opens” and that the Class “A” circuit between the isolator and the insuite sounders it supervises is wired correctly.

- Remove the magnet. The circuit will restore to “normal” operation.

- Place the magnet used in Step 1 on the letter “S” (Short) on the face of the UEI-1. This will impose a “short circuit” on the suite devices under test and cause a “trouble” fault signal at the common control (some systems may actually indicated a “short fault” condition).

- With the magnet still positioned on the “S” (Short), initiate a “Drill Test” from the control unit. The sounders associated with the suite to which the activated ILSTS UEI-1 is connected will not function. All the suite sounders in the other suites in the floor area should operate normally.

- Remove the magnet. The sounders associated with the suite under test will activate.

- Return the magnet to the letter “S” (Short) on the face of the ILSTS UEI-1. The sounders associated with the suite under test will stop functioning. All other in-suite sounders in the floor area should continue to function.

- Remove the magnet. The sounders associated with the suite under test will re-activate.

- Turn off the “drill test” and move to the next ILSTS UEI-1 in the floor area to repeat Steps 1 - 8.

NOTE: If, in step 4, none of the buzzers in the suites sound, then the notification appliance circuit is programmed incorrectly! Some systems utilize a jumper setting to activate the signals if isolators are on the circuit. Other systems require access to the physical panel programming to enable this feature. Regardless, note this on your report as a deficiency because the connect suite signals will not function as required!

For a Verification test (performed to CAN/ULC-S537-13), if you suspect that the number of in-suite sounder or visual appliances connected to the isolator may exceed its rated capacity, you can confirm the total current draw on the isolator for each suite. The ILSTS UEI-1 makes this a simple test to perform. With your multi-meter set to measure current, insert your test leads into the two holes on the face of the unit marked “I+” and “I-”. Position a magnet over the letter “O” on the face of the UEI-1 and initiate a “Drill Test”. The current reading on your meter is the total current drawn by all of the insuite signals which the isolator you’re testing is protecting.

You DO NOT need to remove any fire alarm field device (suite sounder, or cover plate). The entire test for each suite, where ILSTS UEI-1 is utilized takes between fifteen and thirty seconds!

|

|

|

|

|

- Can I retrofit the ILSTS UEI-1 into my existing system that employs suite sounder isolators?

|

|

You can deploy ILSTS UEI-1 into your existing system. You will, in most instances require a building and electrical permit as you are adding devices to an existing fire alarm system. You will have to engage the services of a Verifier in order to obtain an acceptable CAN/ULC-S537 Appendix “C” Report.

In most cases, the cost for the installation will be repaid within two (2) years with the savings you’ll realize from the reduced expense associated with your system’s annual inspection!

|

|

|

|

|

- What's the testing procedure for power and audio buss isolators?

|

|

These units ensure that the common power supply or notification circuit buss is not compromised by a short on one (or a series) of the field devices it serves. These are fairly uncommon on systems installed to date, but where they are used, an appropriate test must be conducted to ensure their operation.

In EVERY case, follow the manufacturer’s suggested test methods and note the results in your report.

Conventional Testing Method:

While shorting a power supply is not normally recommended, opening the circuit on the “out” side of the isolator will identify the devices it protects. You must ensure the maximum current for the unit is not exceeded (or the recommended maximum number of devices). Use your meter (set to “amps”) to determine what each isolator is handling. If the manufacturer’s test method requires you to short the “out” side of the isolator, then proceed as follows:

- Short the circuit using a jumper wire or a pair of needle-nose pliers. This will cause a short condition on the circuit and activate a visible indicator on the isolator being tested.

- Initiate the required testing for devices connected to the buss outside of the floor area served by the isolator under test.

- Remove the short. All indications for the designated buss at the control panel should read “normal”. Some control panels may require a “Reset”.

- Ground one of the terminals against the backbox. A “ground fault” condition should be indicated on the common control.

- With the “ground fault” condition active, complete the required testing procedure for connected fire alarm devices within the floor area.

- Remove the ground. Circuit indications for the DCL (SLC) loop being tested should read “normal” at the common control. You will have to reconnect everything and reinstall your isolator. You may also have to reset the system before proceeding to the next isolator on the loop.

Testing Method with ILSTS UEI-1 Universal Alarm Circuit / Isolator Test Point

|

- Place a magnet on the letter “O” (Open) on the face of the ILSTS UEI-1. Devices downstream of the isolator may report an “open circuit” fault at the common control. You may also observe a “power supervisory trouble”.

- With the magnet in place and your multi-meter set to measure current (Amps), insert the probes into the two holes marked “I-” and “I+” provided on the cover. The circuit will restore to “normal” and your meter should be reading the current draw on the portion of the circuit the isolator is protecting.

- Remove the meter probes. The circuit will reenter a “trouble condition”.

- Remove the magnet. Some panels may require a “Reset”. The circuit will restore to “normal” operation.

- Place the magnet used in Step 1 on the letter “S” (Short) on the face of the ILSTS UEI-1. This will cause a short condition on the circuit and activate a visible indicator on the isolator being tested.

- With the magnet in place, initiate the required testing for devices connected to the buss outside of the floor area served by the isolator under test.

- Remove the magnet. All indications for the designated buss at the control panel should read “normal”. Some control panels may require a “Reset”.

- Insert the test probe from your multi-meter into one of the holes on the face of the unit and ground the other end of the probe against one of the exposed screws used to secure the plate to the electrical box. A “ground fault” condition should be indicated on the common control.

- With the “ground fault” condition active, complete the required testing procedure for connected fire alarm devices within the floor area.

- Remove the probe and disconnect the connection to the building ground. Circuit indications for the power or audio buss riser being tested should read “normal” at the common control. You may have to reset the system before proceeding to the next isolator on the loop.

For a Verification test (performed to CAN/ULC-S537-13), if you suspect that the voltage supplied to powered devices in the floor area that the isolator is protecting, set up you meter to read DC Voltage, and simply insert your meter leads into the two holes marked “V-” and “V+” on the face of the unit. The reading on your meter is the voltage coming off the isolator.

Note: If Steps 3 and 4 are accidentally reversed, the circuit will not be adversely affected.

You DO NOT need to remove (or disassemble) any active field device on the circuit serving the floor area. The entire test using ILSTS Universal Alarm Circuit / Isolator Test Point (UEI-1) takes just fifteen seconds!

|

|

|

|

|

- What are the tests required for a Class "A" (Style 6 in the USA) circuit?

|

|

In Canada, the testing for conventional Class “A” circuits is specified in CAN/ULC-S537-13 Clause 3.3.1.3. You have to inspect and test for the circuit’s ability to generate an alarm signal on both sides of a single “open fault” condition at an “electrically remote point in the circuit”. You also have to test for “ground fault” and voltage at the electrically furthest field device. Typically, this requires removing a device somewhere in the area (or zone) to perform the “open circuit” portion of the test. Installing an ILSTS UEI-1 adjacent to the fire alarm common control (or booster power supply) can facilitate these tests, but won’t allow you to check for operation of field devices on either side of an “open”. You can easily install a UEI-1 in the floor area (at close to the midpoint of the circuit). Make sure you mount it at a height of 1800 mm or less (to the centre of the device) and label it as the area’s (or zone’s) Class “A” test point. The “ground fault” and voltage drop test can be conducted right at the control panel in a Class “A” circuit.

|

|

|

|

|

- What are the tests required at each end-of-line resistor?

|

The testing requirements were first introduced in CAN/ULC-S536-04. Section 5.7.11 is entitled Conventional Circuit End-of-Line Device and requires you to test each input circuit and output circuit end-of-line devices for open circuit (supervision), short circuit (alarm or supervisory), and ground fault conditions. You must, furthermore record the results of each test in the inspection report. What this means is that you will have to FIND every end-of-line device (it's usually mounted on a single gang plate which is appropriately labeled), and drop it to perform your tests. This will add approximately five (5) to ten (10) minutes for every zone on the system. On older systems, you may have to hunt for them as they may have been mounted behind the last device in the circuit and not on an identifiable plate. You must list each device in the test record along with its location. The number of end-of-line devices should match the number of active zones on a conventional fire alarm system.

Testing method using ILSTS UEI-1 Universal Alarm Circuit / Isolator Test Point

- Place a magnet on the letter “O” (Open) on the face of the ILSTS UEI-1. This will cause the control panel to display an “open circuit trouble” supervisory fault indication.

- Remove the magnet. The circuit should restore to “normal” operation.

- Place the magnet used in Step 1 on the letter “S” (Short) on the face of the UEI-1. This will cause a short on the circuit. If it’s programmed as an “alarm”, the appropriate red indicator should illuminate at the common control (and all installed annunciators). If it’s programmed as a “supervisory”, the appropriate yellow indicator should illuminate.

- Remove the magnet and “Reset” the system.

- Insert a test probe from your multi-meter into one of the holes on the face of the ILSTS UEI-1 and ground the other end of the probe against one of the exposed screws used to secure the wall plate to the electrical box. The fire alarm control will indicate a “trouble” condition (some fire alarm controls may indicate a “ground fault” or “earth fault” condition).

- With your multi-meter set for reading “DC Volts”, you will be able to measure the voltage across the end-of-line resistor by inserting your test probes into the two holes marked “V-” and “V+” on the face of the ILSTS UEI-1. This is a required test for CAN/ULC-S537 (Standard for Verification of Fire Alarm Systems). On notification appliance circuits you will want to ensure you’re measuring the voltage while the system is “in alarm” and all audible/visual devices are active.

- Check to make sure the function (or circuit identification) is clearly legible on the face of the ILSTS UEI-1. This is a requirement of CAN/ULC-S524 (Standard for Installation of Fire Alarm Systems).

Additional Testing Notes:

For a Verification (to CAN/ULC-S537), you may wish to confirm the current draw on the notification appliance circuit you’re testing. ILSTS UEI-1 makes this test easy to accomplish:

- Set up your meter to read current (Amps) and insert the test probes into the two holes marked “I-: and “I+” on the front of the ILSTS UEI-1;

- Place a magnet over the letter “O” on the face of the UEI-1 and keep it there;

- Initiate a “Drill Test”. The current you see displayed is the total current for the circuit being tested;

- Turn off the “Drill Test”;

- Remove the magnet and the test leads from your meter;

- The circuit should indicate “normal” operation (no zone fault).

You can also easily confirm that the correctly sized end-of-line resistor is installed on the circuit without having to dismount the ILSTS UEI-1:

- Set your meter to measure “Ohms”,

- Position a magnet over the letter “O” (Open) on the face of the ILSTS UEI-1,

- Insert your test leads into the two holes marked “V-” and “V+”. The reading you see displayed is the value of the installed resistor.

- Remove your test leads

- Remove the magnet. The circuit will restore to normal.

You DO NOT need to remove or drop any field devices. All of the tests on this page can be accomplished from the face of the ILSTS UEI-1 and takes less than fifteen seconds to complete the testing of each end-of-line resistor as required by CAN/ULC-S536-13 (Standard for Inspection and Testing of Fire Alarm Systems) Section 6.7.11 Circuit End-of-Line Device !

|

|

- Can I retrofit my currently installed end-of-line plates with ILSTS UEI-1?

|

|

Most definitly! In most cases, you will require an electrical permit (obtained through your local civic government) and a Verification (to CAN/ULC-S537). The UEI-1 can be used to replace a damaged (or painted) end-of-line plate in which case a permit may not be required (it’s considered a repair). Check with your local Authority Having Jurisdiction. They may require you to retest the affected circuit(s). Once replacement has been accomplished, the annual testing time will be significantly reduced for every circuit (or zone) supervised by an ILSTS UEI-1.

|

|

|

|

|

- What is Larrstep (also referred to as the Larrstep EEL-1), and how does it compare to the ILSTS UEI-1?

|

|

Larrstep™ EEL-1

There isn’t a lot of information on the website at www.larrstepinc.com about the Larrstep EEL-1 other than that it is being largely advertised as an end-of-line testing solution (a fact that’s borne out when you reference the product’s Patent). We are providing some additional information for anyone contemplating the installation and implementation of the Larrstep EEL-1 product for a life safety (fire alarm) system, in order to assist you in identifying where it can (and cannot) be utilized:

- The most critical fact is that it’s limited to a maximum switching current of 100 mA (0.1 Amps);

- In some Canadian applications the building’s fire alarm system can’t differentiate between a ground fault and a common trouble signal. When the ground wire on the EEL-1 is terminated and the key switch is moved to the open circuit test position, a ground fault is simultaneously imposed on the circuit. Since both Canadian Testing Standards require you to be able to clearly differentiate the two trouble conditions, you may have to forgo terminating the ground wire on some fire alarm systems;

- Installation in unconditioned environments (like sprinkler rooms or parkades) could compromise its operation;

- The unit cannot be used to test power or audio buss riser isolators (in fact, our research suggests that it shouldn’t be utilized to test ANY isolator);

- The EEL-1 should NOT be used on a notification appliance circuit (NAC), where shorting currents greater than 100 mA (up to as high as 2.5 amps) can easily be expected; and

- The keys can be easily misplaced which would make operation of the device impossible as they are not standardized to the fire alarm control being tested.

ILSTS UEI-1 Universal Alarm Circuit / Isolator Test Point

ILSTS’s Universal Alarm Circuit / Isolator Test Point (which will be undergoing evaluation by UL and ULC shortly), can switch up to 3 Amps of current, doesn’t rely on proprietary keys, and will allow fire alarm technicians to perform the proper testing of isolators serving suite signaling circuits, data communication links, power supplies, and power and audio busses, in addition to standard conventional circuits.

The ILSTS UEI-1 is a simple. effective, reliable, and economical device that’s designed to facilitate the required testing of various fire alarm circuits in conformance with CAN/ULC-S537 (Standard for Verification of Fire Alarm Systems), CAN/ULC-S536 (Standard for Inspection and Testing of Fire Alarm Systems), CAN/ULC-S561-13 (Standard for Installation and Services for Fire Signal Receiving Centres and Systems), and CAN/ULC-S1001-11 (Standard for Integrated Testing of Fire Protection and Life Safety Systems).

The UEI-1 joins a growing family of products and services we provide that are the only truly universal fire alarm and life safety systems testing solutions on the market!

For all of the latest news regarding our products and services, please take a moment to visit our News Centre!

Priced at less than $9.00 (CDN), ILSTS UEI-1 is not significantly more expensive than your standard end-of-line plate! For the System Designer, the case for specifying ILSTS UEI-1 is an easy one to make because of the many benefits the building owner / operator will derive! (Did we mention it comes with a life-time warranty?)

|

|

|

- What is Offside Technologies Corp's SM-001, and how does it compare to the ILSTS UEI-1?

|

|

Offside Technologies Corp. Electronic Verifying Switch (EVS) SM-001

This is a device being manufactured under the Larrstep™ Patent by Stephen and Mark Ainsworth. Stephen happens to be Larrstep’s co-inventor (Larry Geoghegan of Larrstep, Inc. is the other). The EVS actually represents a radical departure from the product both Larry and Stephen originally envisioned because it employs a four position key-switch (where the Larrstep unit uses a three position one). Here’s what we know (from our review of their website at www.offsidetechnologies.com):

- The Electronic Verifying Switch (EVS) is limited to a maximum switching current of 350 mA (0.35 Amps);

- The four switch positions (in a clockwise sequence) are “N” (Normal), “O” (Open Circuit), “G” (Ground), and “S” (Short). In order to perform the short test, you need to switch through two other trouble conditions from the “normal” circuit position;

- Installation in unconditioned environments (like sprinkler rooms or parkades) could compromise its operation. You can order a set of rubber caps (which can be easily misplaced) for installations where water may “drip” on the unit or if the environment is dusty, but it is only approved for indoor, dry applications (we would suggest that the unit should not be installed in dusty environments as the switch and other components are not intrinsically safe);

- The unit cannot be used to test power or audio buss riser isolators (in fact, our research suggests that it should only be utilized for a limited number of data communication link circuit applications);

- You will need TWO (2) EVS devices to test a single leg of an in-suite signal circuit isolator for a total of FOUR (4) units per isolator. This is because you need to be able to return the circuit to “normal” as you conduct the required testing of the isolator;

- The EVS should NOT be used on a signalling circuit, where shorting currents greater than 350 mA can easily be expected; and

- The keys can be easily misplaced which would make operation of the device impossible as they are not standardized to the fire alarm control being tested.

We are also extremely troubled that a number of testing procedures demonstrated (and outlined in the EVS testing instructions) on the Offside Technologies website actually contravene the Canadian testing and Verification Standards. For instance:

- You cannot install the unit to conveniently perform the required short test for a conventional fixed temperature heat detector.

The proper way to test a fixed temperature non-restorable heat detector is articulated in CAN/ULC-S536-13 Sentence 6.7.3.3 “Each non-restorable heat detector shall have the circuits tested by simulating its electrical operation at the wiring connection.”

- You cannot install the unit to test inaccessible fire detectors. One prominently featured photograph depicts a view from the top of a stairwell and the accompanying text suggests that the EVS device can be utilized as an approved test point for a detector in this location.

Fire detectors come in two “flavours”: “addressable” and “conventional”. Installing the EVS device to test an addressable fire detector will actually short the data communication link circuit. For smoke detectors installed in these locations, the correct testing method is articulated in CAN/ULC-S536-13 Sentence 6.7.4.1.2 “Each smoke detector shall be tested for operation by introducing smoke or simulated smoke to the detecting chamber in accordance with the manufacturer’s instructions.” For restorable heat detectors, the testing requirement is articulated in Sentence 6.7.3.2 “Each restorable heat detector shall be tested by using a heat source reproducible in its intensity, as recommended by the manufacturer of the device, to initiate an alarm.”

- The “open circuit” test mentioned on the data communication link side of a monitor module (supporting field device) is NOT a required test in any published edition of CAN/ULC-S536 (Standard for Inspection and Testing of Fire Alarm Systems).

- The “short on alarm” test is actually missing from the website’s “Testing Procedure for In Suite Isolator Device” (likely because of the key-switch’s maximum current limitation). This means that a technician will still have to drop the insuite sounder to perform this critical operation.

The testing method for isolators serving suites of a residential occupancy is articulated in CAN/ULC-S536-13 Sentence 6.7.9.2 F “Where signal circuit suite isolator devices are used in suites of residential occupancies they shall be inspected and tested to confirm operability. Where a signal circuit serves more than one residential suite, a wire-to-wire short circuit fault shall be imposed within each suite in a normal (supervisory non-alarm) and alarm conditions. In all cases the wire-to-wire short circuit fault shall not interfere with the ability of devices in other dwelling units, public corridors, or suites to sound an alarm.”

- The “open circuit” test method demonstrated on the source side of a data communication link isolator is NOT a required test in any published edition of CAN/ULC-S536 (Standard for Inspection and Testing of Fire Alarm Systems). The instructions also suggest that you will require two (2) EVS units in the floor area. The testing of the data communication link isolators serving a Class “A” Style “C” circuit only requires a single “open”, “short” and “ground fault” be introduced in each floor area (and the activation of a field device on the source side while these individual troubles are present).

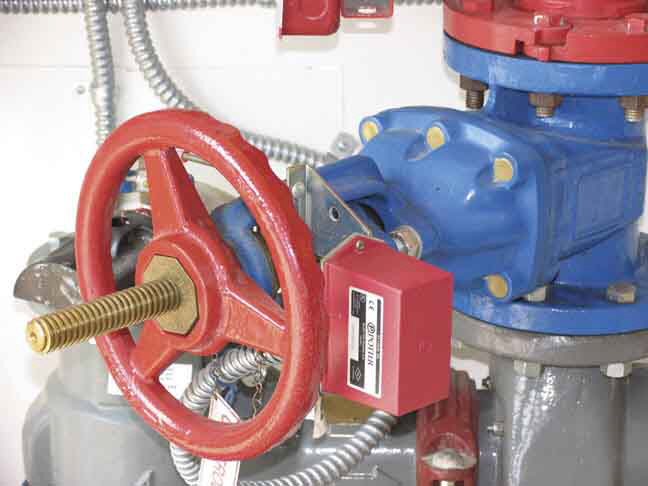

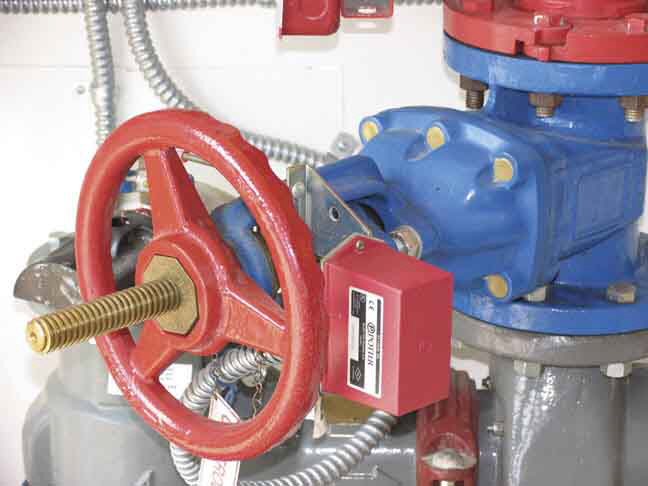

- Technicians cannot utilize the unit to simulate the actual activation of a sprinkler flow, valve, or other supervisory switch. Flow switches MUST be tested by the required water-flow means available (which may require a sprinkler technician to operate) and the testing technician must record the time-to-alarm, etc on the Individual Device Record. Other sprinkler supervisory devices must be tested in accordance with the Standard (and their specific operational parameters may need to be recorded). Valves have to be operated to ensure their supervisory switches function within the Standard’s required parameters (two turns of the valve handle or movement of the valve stem beyond 20% of the normal open position).

Reference CAN/ULC-S536-13 Section 6.7.8 Devices for Water Type Extinguishing Systems for the required annual testing of these devices.

- You cannot use the EVS to “bypass” interconnected alarm functions in order to test ancillary alarm or supervisory devices like kitchen suppression releasing systems. Both NFPA 17A and CAN/ULC-S536 REQUIRE witnessing the correct operation and the fire alarm system’s activation (including remote annunciation) at every test that’s conducted of this equipment.

The reference in CAN/ULC-S536-13 is 6.7.8.3.1 “Where a fixed type extinguishing system is connected to the fire alarm control unit or transponder, confirm the operation of the output contacts of the extinguishing system panel initiates the specified system functions at the fire alarm control unit or transponder (e.g. alarm, trouble).”

ILSTS UEI-1 Universal Alarm Circuit / Isolator Test Point

ILSTS’s Universal Alarm Circuit / Isolator Test Point (which will be undergoing evaluation by UL and ULC shortly), can switch up to 3 Amps of current, doesn’t rely on proprietary keys, and will allow fire alarm technicians to perform the proper testing of isolators serving suite signaling circuits, data communication links, power supplies, and power and audio busses, in addition to standard conventional circuits.

The ILSTS UEI-1 is a simple. effective, reliable, and economical device that’s designed to facilitate the required testing of various fire alarm circuits in conformance with CAN/ULC-S537 (Standard for Verification of Fire Alarm Systems), CAN/ULC-S536 (Standard for Inspection and Testing of Fire Alarm Systems), CAN/ULC-S561-13 (Standard for Installation and Services for Fire Signal Receiving Centres and Systems), and CAN/ULC-S1001-11 (Standard for Integrated Testing of Fire Protection and Life Safety Systems).

The UEI-1 joins a growing family of products and services we provide that are the only truly universal fire alarm and life safety systems testing solutions on the market!

For all of the latest news regarding our products and services, please take a moment to visit our News Centre!

Priced at less than $9.00 (CDN), ILSTS UEI-1 is not significantly more expensive than your standard end-of-line plate! For the System Designer, the case for specifying ILSTS UEI-1 is an easy one to make because of the many benefits the building owner / operator will derive! (Did we mention it comes with a life-time warranty?)

|

|

|

|

|

|

|

|

|

|

|

|

Made in Canada, eh!

|

|

Copyright © 2014 - 2021 Integrated Life Safety Testing Solutions Inc. - All Rights Reserved

|

|

The Legal Stuff

|

|

|

|

|

|